Automatic Liner Cutting and Insertion Machines

Automatic Liner Cutting and Insertion Machines Specification

- Drive

- Electric

- Control System

- Fully Automatic

- Country Of Origin

- India

- Features

- High Quality

- Frequency

- 50/60 Hertz (HZ)

- Voltage

- 220-440 Volt (v)

- Product Type

- Automatic Liner Cutting and Insertion Machines

- Power Source

- Electricity

- Color

- Silver

- Warranty

- 1 Year

- Usage & Applications

- Industrial

Automatic Liner Cutting and Insertion Machines Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 7 Days

About Automatic Liner Cutting and Insertion Machines

Description

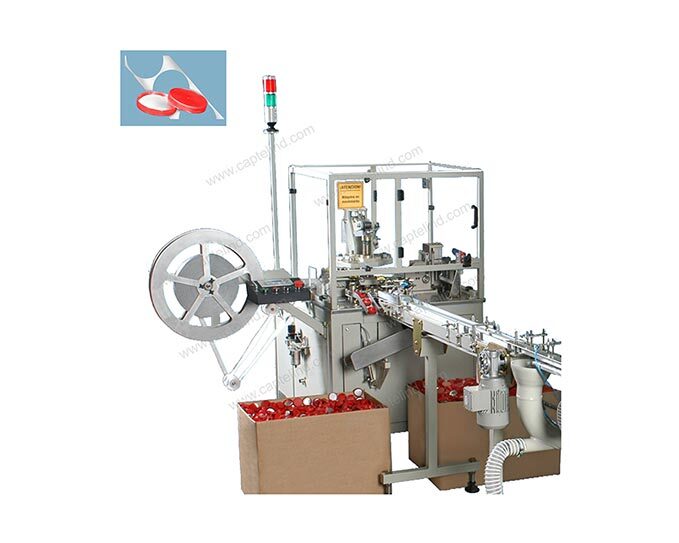

Our Wadding Machines for Cutting & Fixing Liners in Closures are designed for packaging lines to automatically cut liners from rolls and insert them into caps in a single step. Caps are manually loaded into a vibratory or elevator hopper, oriented, and moved to a dial for precise positioning. Liners are fed onto in-feed rollers, cut just before the wad punching station, and then dropped into the cap. A pusher firmly secures the liner inside. The assembled caps are then counted and discharged from the conveyor. The machine is versatile, handling various cap and liner types with interchangeable change parts. Available with or without a hot gluing system, it supports one-piece, two-piece, and EPE liners.

Sizes Available

- For Various Cap Sizes

- Customisation Options

Automatic Liner Cutting and Insertion Machines are designed to meet functional and safety requirements in packaging applications. Ensures secure sealing to prevent leakage during storage and transport.

Features & Specifications

- Vibratory or Elevator Hopper for smooth feeding of caps.

- Conveyor moves caps to the next process station.

- Dial with Indexed Locations holds caps in exact position for proper processing.

- Infeed rollers feed liner rolls into the machine.

- Liner Cutting Station cuts liners to the required size.

- Wad Punching Station places cut liner into the cap.

- Pusher fixes the liner firmly inside the cap.

- Counting Mechanism counts the assembled caps.

- Hot Glue System (Optional) for adhesive fixing of liners when required.

- Speed Options - works at 60 or 120 caps per minute with single head and 120 or 240 caps per minute with double head.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Cap Liner Inserting Machine Category

Liner Insertion Machines for Closures

Minimum Order Quantity : 1 Piece

Control System : Fully Automatic

Power Source : Electricity

Voltage : 220440 Volt (v)

Features : High Quality

Country Of Origin : India

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese